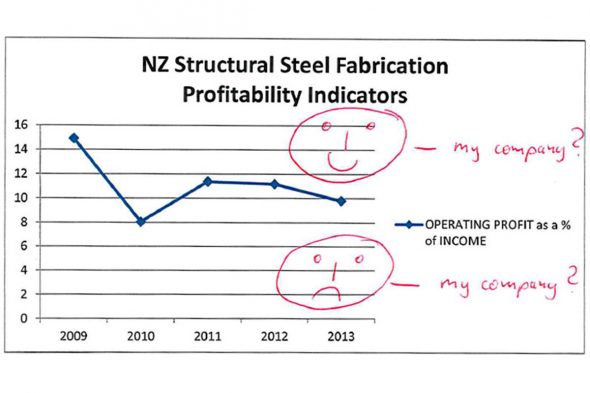

#MIC2015 – HERA attends the Steel Innovations Conference

The Aotea Event Centre was a well selected venue to the second Steel Innovations Conference during Metals Week held on the 1 – 4 September. First launched in 2013, the biannual Steel Innovations Conference provides a forum for structural engineers, steel industry representatives, academics and students to share the latest knowledge in the design and…